Smart Weigh is a leader in the design, manufacture and installation of complete weighing and packing solutions. Such solutions range from designing and setting up entire new packing halls to providing a single machine to perform a specific task.

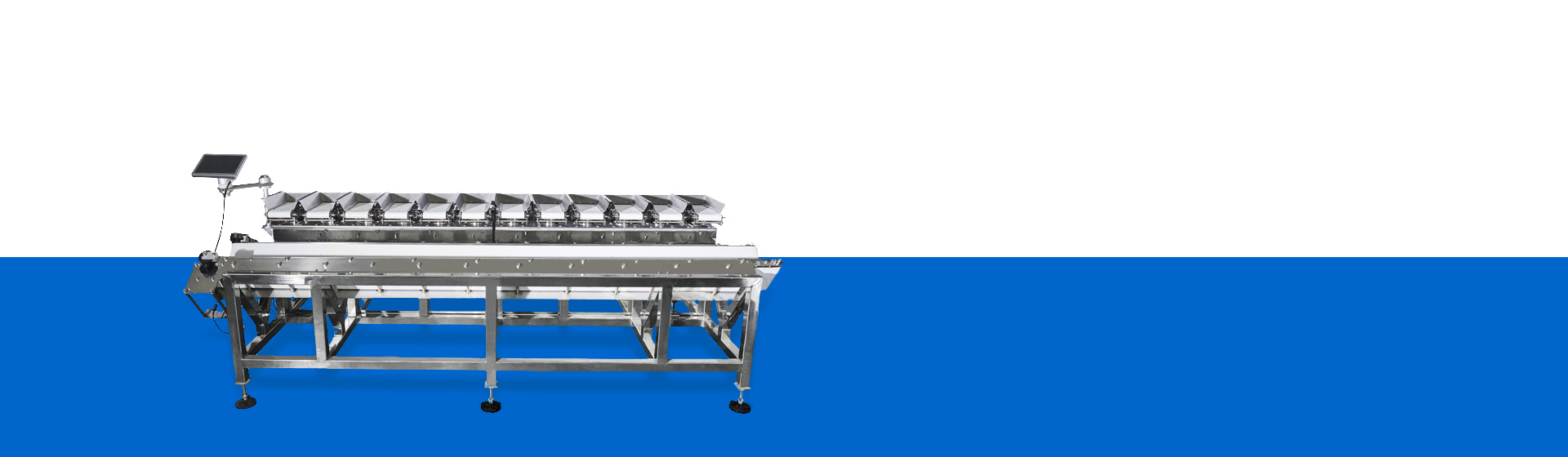

Smart Weigh designs and builds multihead weigher, linear weigher,linear combination weigher, check weigher, tray denester, Z bucket conveyor, incline conveyor, working platform, VFFS vertical form fill seal packing machine, rotary packing machine etc.

Today our sharing is potato chipsvertical packing machineline.

Potato chips packing line is connect with potato chips production line, it contain Z bucket conveyor, multihead weigher, working platform, VFFS form fill sealpacking machine、输出输送机,转盘,nitrogent generator etc.

People definitely watch far fewer TV commercials today than they did 20 years ago, for example, and it’s becoming much more difficult to reach the client in other traditional ways, so the importance of good packaging will continues to grow in terms of package design and how well it communicates with the consumers.

Smart Weigh can provide various package design and packing solution based on clients’ roughly budget and needs.

For bag package, there are pillow bag, gusset bag, quad bag, doypack, box bag that you can prefer, which is your best choice?

For product’s value is high, and want to sell with a good price, and want the bag can stand on the shelf, we would like to recommend quad bag, doypack, their bag shape are really nice; if product’s value is not so high, and want to win client with a competive price, so we would like to recommend pillow bag, gusset bag. For product like chips, most client will choose pillow bag.

Usually, the packaged potato chips are bagged in nitrogen filling bags to protect them from being oxidized. Nitrogen generator is suitable for crisp snacks and puffed food like potato chips, popcorn, chips etc.

Watch how a completeSmartWeigh packing solutionhelped Myanmar potato chips manufacturer automate their production line -

achieving around 150kg(4200 bags)via two employees per hour compared to 840 when all operation was carried out manually.

Our chips client can save space, money via choosing Smart Weigh multihead weigher packing line.

Packaging has always been a very important marketing vehicle, and it is becoming even more important as efforts to build brands are becoming ever more complex, due to the influence of traditional media declining in our collective lives.

Smart Weigh will be your best package designer!