Thermoforming vacuum packing muchina wekudya kwakabikwa

TUMA KUBVUNZA ZVINO

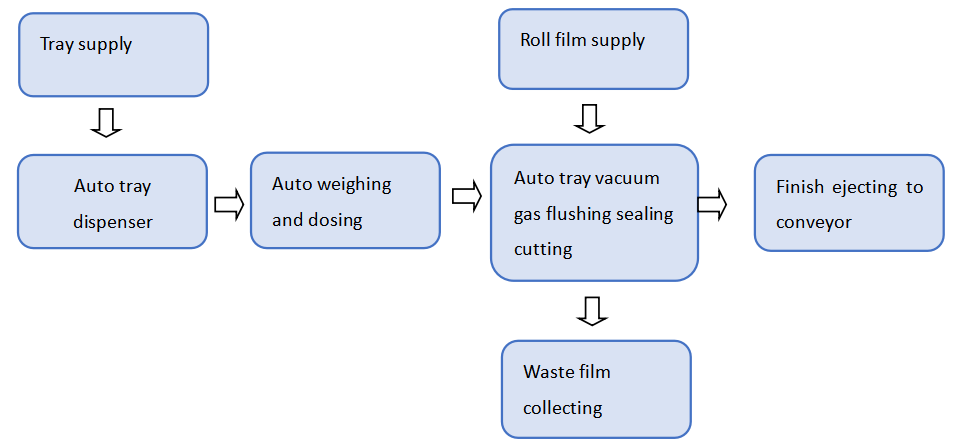

Zvakakwana otomatikilinear tray yekuzadza sealing muchinainogona kurodha matireyi asina chinhu, kuona matireyi asina chinhu, auto quantitative kuzadza chigadzirwa mutireyi, otomatiki firimu kudhonza uye kuunganidza tsvina, otomatiki.tray vacuum gasi kutsvaira, kuisa chisimbiso uye kucheka firimu, kuburitsa otomatiki chigadzirwa chekupedzisira kune conveyor. Kugona kwayo 1000-1500trays paawa, inokodzera chikafu chekugadzira fekitori zvinodiwa.

Muchina wese wakagadzirwa nesimbi isina tsvina 304 uye anodizing aruminiyamu, ive nechokwadi kuti unokwanisa kumhanya pane yakaipa chikafu fekitori nharaunda ine nyoro, chipfunga, mafuta, acidity uye munyu nezvimwe.

Uchishandisa emhando yepamusoro zvikamu zvemagetsi zvinotengeswa kunze kwenyika uye zvikamu zvepneumatic izvo zvinovimbisa kugadzikana kushanda kwenguva yakareba, kuderedza kumira uye kugadzirisa nguva.

1.Driven system: servo mota ine gearbox yetireyi molds inotsika ichimhanya, inogona kufamba yakazadzwa tireyi nekukurumidza asi inodzivirira zvinhu splash nekuti servo mota inogona kutanga nekumira zvakanaka, uye zvakare yakakwirira positioning kururama.

2. Empty tray loading function: inoshandisa spiral kupatsanura nekutsikirira tekinoroji iyo inogona kudzivirira kukuvara kwetireyi nekuremara, ine vacuum sucker inotungamira tireyi kupinda mukuumbwa kwayo.

3.Empty tireyi yekuona basa: inoshandisa photoelectric sensor kana optical fiber sensor kuti ione mold ine kana isina tireyi isina chinhu, inogona kudzivirira kukanganisa kuzadza, kuvhara uye kuvhara kana mold isina matireyi, kuderedza chigadzirwa tsvina uye nguva yekuchenesa muchina.

4. Quantitative kuzadza basa: akawanda-musoro akangwara akasanganiswa kuyera uye yekuzadza sisitimu inogamuchirwa kuita yakakwirira-chaiyo kuyera uye kuwanda kuzadza kune akasiyana akaumbwa zvinhu zvakasimba. Zviri nyore uye nekukurumidza kugadzirisa uye ine diki kukanganisa muhuremu hwegiramu. Uchishandisa servo drive material distributor, chaiyo positioning, diki kudzokorora chinzvimbo kukanganisa, kushanda kwakagadzikana

5.Vacuum gasi flushing system: inogadzira pombi yevacuum, mavharuvhu, mavharuvhu egasi, mavharuvhu ekuburitsa mhepo, vharafu inodzora vharafu, sensor sensor, vacuum chambers etc. inopomba mweya uye jekiseni gasi kuti iwedzere hupenyu hwesherufu.

6.辊firimu密封yekucheka波沙:Iyo sisitimuine otomatiki dhirowa remufirimu, nzvimbo yekudhinda firimu, tsvina yekuunganidza firimu uye thermostat yekuisa chisimbiso system, yekuisa chisimbiso inogona kumhanya nekukurumidza uye inowana pane yakadhindwa firimu nemazvo. Thermostat yekuisa chisimbiso yekucheka system inoshandisa Omron PID tembiricha controller uye sensor yemhando yepamusoro yekuisa chisimbiso.

7.Discharge system: inogadzira nekusimudza tireyi uye kudhonza hurongwa, ejection conveyor, iyo yakarongedzwa trays inosimudza uye kusundira kune conveyor nekukurumidza uye yakagadzikana.

8.Automation control system: inogadzira nePLC, Bata skrini, servo system, sensor, magineti valve, relays nezvimwe.

9.Pneumatic system: inogadzira nevharuvhu, mhepo sefa, mita, kudzvanya sensor, magineti valve, macylinders emhepo, silencer nezvimwe.

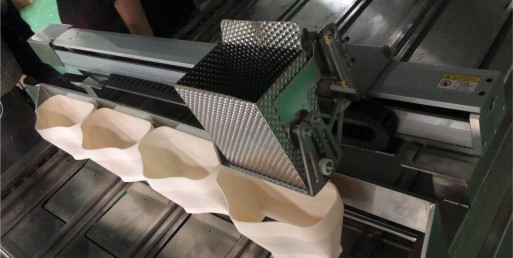

Vacuum gasi rekutsvaira yekuisa chisimbiso chekucheka mudziyo

Inoyerera chati yekurongedza

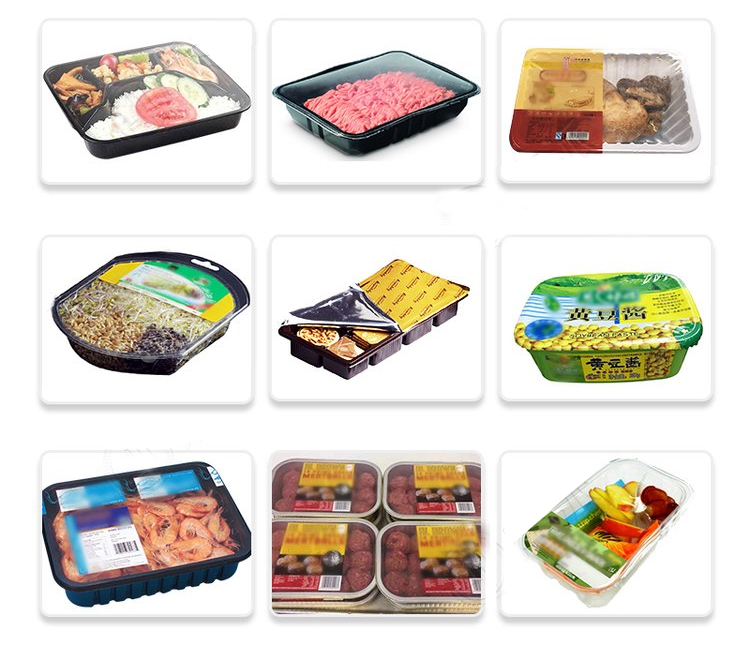

Inoshandiswa zvakanyanya kune matireyi ehukuru hwakasiyana uye maumbirwo. Izvi zvinotevera chikamu chekurongedza mhedzisiro show

TAURA NESU

Kuvaka B, Kunxin Industrial Park, Nhamba 55, Dong Fu Road, Dongfeng Town, Zhongshan Guta, Guangdong Province, China, 528425

Wana Mashoko Emahara Ikozvino!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved