Ka ho feletsengmochini o tiisang oa linear tray fillinge ka kenya li-tray tse se nang letho, ho bona li-trays tse se nang letho, sehlahisoa sa ho tlatsa li-auto quantitative ka har'a terei, ho hula filimi ka boiketsetso le ho bokella litšila, ka bohona.ho hlatsuoa ka khase ka tereing, ho tiisa le ho seha filimi, ho ntša sehlahisoa sa ho qetela ho conveyor. Bokhoni ba eona ba 1000-1500trays ka hora, bo loketse litlhoko tsa tlhahiso ea feme ea lijo.

Mochini oohle o entsoeng ka tšepe e sa hloekang 304 le anodizing aluminium, o netefatsa hore o ka sebetsa tikolohong ea fektheri e mpe ea lijo e nang le mongobo, mouoane, oli, acidity le letsoai joalo-joalo 'mele oa eona o ka amohela ho hlatsoa ha metsi ho hloekile.

何鸿燊sebelisa likarolo tsa motlakase tsa boleng bo holimo tse tsoang kantle ho naha le likarolo tsa pneumatic tse netefatsang ts'ebetso e tsitsitseng ka nako e telele, ho fokotsa nako ea ho emisa le ho e lokisa.

Mohlala |

SW-2R-VG |

SW-4R-VG |

Palo ea li-volts |

3P380v/50hz |

|

Matla |

3.2kW |

5.5kW |

Mocheso oa ho tiisa |

0-300 ℃ |

|

Boholo ba terei |

L:W≤ 240 * 150mm H≤55mm |

|

Boitsebiso ba ho Tiisa |

PET/PE, PP, Aluminium foil, Pampiri/PET/PE |

|

Bokhoni |

700 literei/h |

1400 literei/h |

Sekhahla sa phetoho |

≥95% |

|

Khatello ea ho noa |

0.6-0.8Mpa |

|

G.W |

680kg |

960kg |

Litekanyo |

2200×1000×1800mm |

2800×1300×1800mm |

Sistimi ea 1.Driven: servo motor e nang le lebokose la li-gear bakeng sa liforomo tsa terei tse hatang li matha, e ka tsamaisa terei e tlatsitsoeng ka potlako haholo empa e qoba ho phatloha ha thepa hobane servo motor e ka qala le ho emisa hantle, hape le ho nepahala ha maemo a holimo.

2. Ts'ebetso ea ho kenya literei e se nang letho: e sebelisa theknoloji ea ho arola le ho hatella e ka qobang tšenyo ea terei le ho holofala, e na le vacuum sucker e tataisang terei hore e kene ka har'a hlobo e nepahetseng.

3. Ts'ebetso ea ho bona tray e se nang letho: e sebelisa sensor ea photoelectric kapa optical fiber sensor ho lemoha hore hlobo e na le kapa e se na tray e se nang letho, e ka qoba ho tlatsa phoso, ho tiisa le ho koala haeba hlobo e se na li-trays, e fokotsa litšila tsa sehlahisoa le nako ea ho hloekisa mochine.

4. Mosebetsi oa ho tlatsa ka bongata: Lihlooho tse ngata tse bohlale tse kopantsoeng ho bekha le ho tlatsa tsamaiso ea ho bekha le ho tlatsa e amoheloa ho etsa boima bo phahameng le ho tlatsa ka bongata bakeng sa thepa e sa tšoaneng e tiileng. E bonolo ebile e potlakile ho ikamahanya le maemo 'me e na le phoso e nyane ka boima ba gram. Ho sebelisa servo drive material distributor, boemo bo nepahetseng, phoso e nyenyane ea ho pheta-pheta, ts'ebetso e tsitsitseng

5.Sistimi ea ho futhumatsa khase ea vacuum: E etsa ka pompo ea vacuum, li-valve tsa vacuum, li-valve tsa khase, li-valve tse lokollang moea, valve e laolang khatello, sensor ea khatello, likamore tsa vacuum joalo-joalo.

6.Roll filimi ho tiisa mosebetsi oa ho itšeha: Sistimi e na le drawer ea lifilimi e ikemetseng, sebaka sa filimi ea khatiso, pokello ea lifilimi tse litšila le sistimi ea ho tiisa thermostat, sistimi ea ho tiisa e ka sebetsa ka potlako mme e fumana filimi e hatisitsoeng ka nepo. Thermostat sealing cutting system e sebelisa Omron PID controller le sensor bakeng sa ho tiisa mocheso oa boleng bo holimo.

7.Sistimi ea ho tsoa: e etsa ka mokhoa oa ho phahamisa le ho hula tray, ejection conveyor, li-trays tse tletseng li phahamisa le ho sutumelletsa ho conveyor ka potlako le ka mokhoa o tsitsitseng.

8.Automation control system: e entsoe ke PLC, skrine ea ho ama, sistimi ea servo, sensor, valve ea makenete, li-relay jj.

9.Sistimi ea moea: e entsoe ka valve, sefahla sa moea, mitha, sensor e hatellang, valve ea makenete, lisilindara tsa moea, silencer jj.

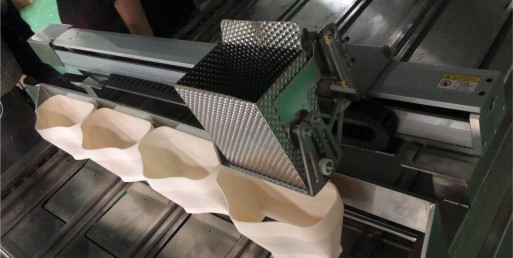

Sesebediswa sa ho seha se tiisang ka kgase ya vacuum

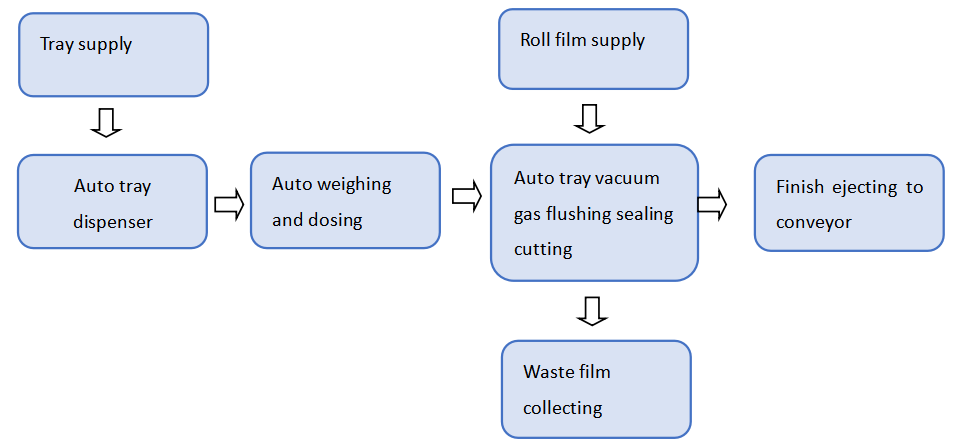

Chate e phallang ea ho paka:

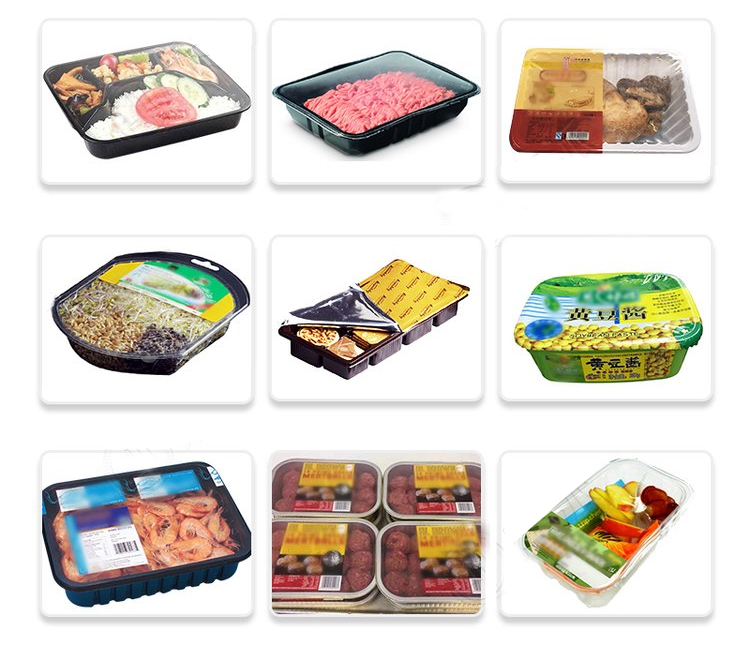

Mehlala:

E sebetsa haholo ho literei tsa boholo bo fapaneng le libopeho. E latelang ke karolo ea pontšo ea phello ea ho paka

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | Litokelo tsohle li sirelelitsoe