Have you ever seen Discovery Plus featuring factories? If yes, you might have seen them introducing new machinery that makes packaging extremely mechanical and robotic-like.

Various machinery can aid you in packing the lightning fast with accuracy. Among them,Multihead weighermachines are prevalent. It separates the bulk quantity of the contents, like dried fruits and candies, and packs them according to the measurements set by the operands.

Want to know more aboutMultihead weighing machinesand how they assist in work? Let's find out together!

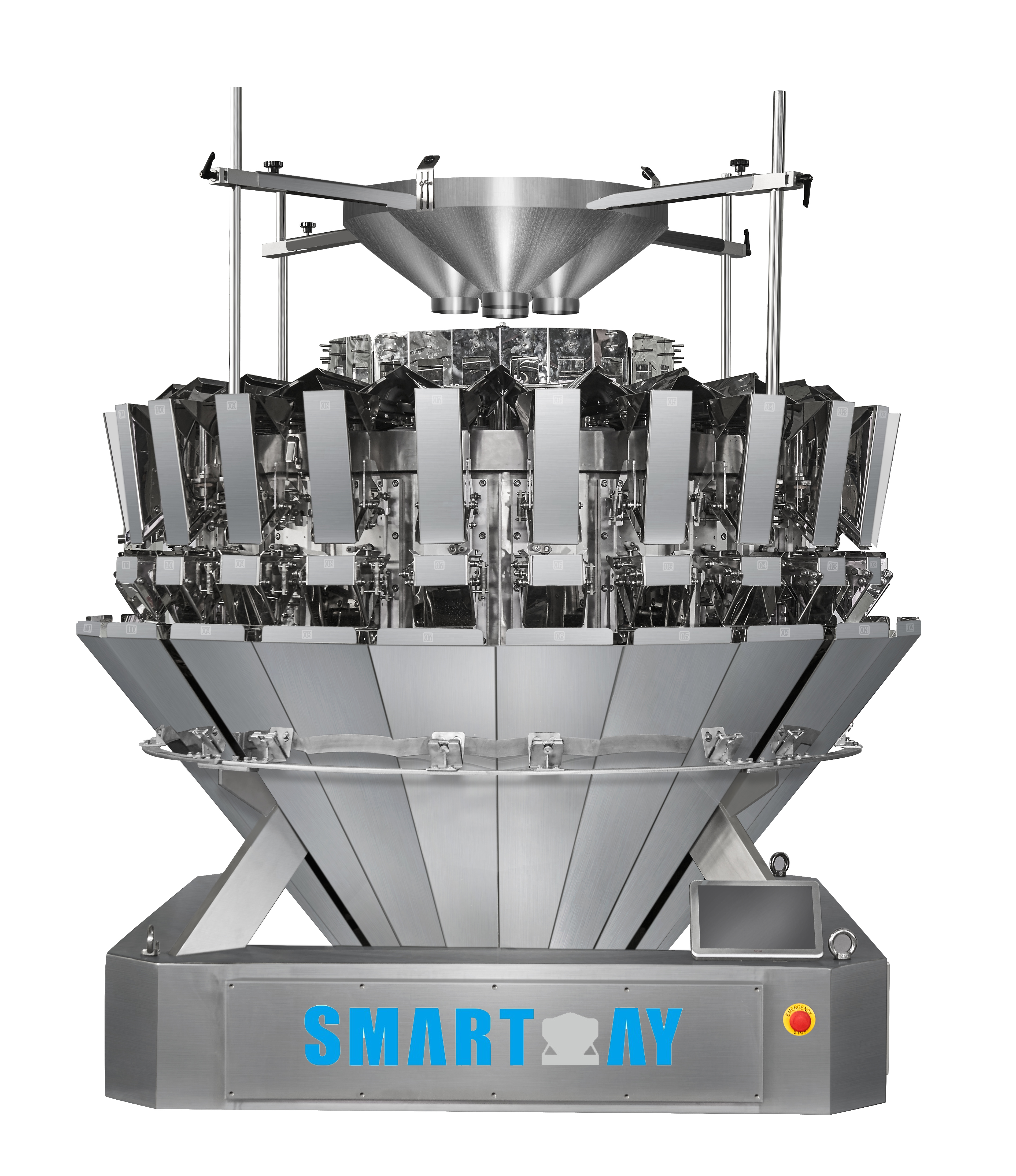

AMultihead weigher machineis the best for packaging cereal, nuts, gummies, snacks, vegetables, etc. It uses multiple weighing heads to weigh then calculate the most accurate weight for discharge. Also, there is a lot of data feeding involved as each head hopper is connected with a load cell.The most prominent qualities of aMultihead weigherare its speed and accuracy. That being the case, it has gained recognition globally and is used at most packaging factories to speed up the process and decrease the burden of human resources.

Not only that, but it can easily be integrated into various other machinery like check andinspection machines to make the working process more efficient—the number of heads on Multihead weigher range from 10 to 32+.

14 head multihead wiegher

14 head multihead wiegher

On average, the number of packages that a Multihead weigher machine ranges from 60-120 packs per min depending on the machine you invest in.

Now that you know the purpose of a Multihead weigher machine, let's get into the main components of a Multihead weigher to get a clear view of its functionalities. Here are some top components of a Multihead weigher machine.

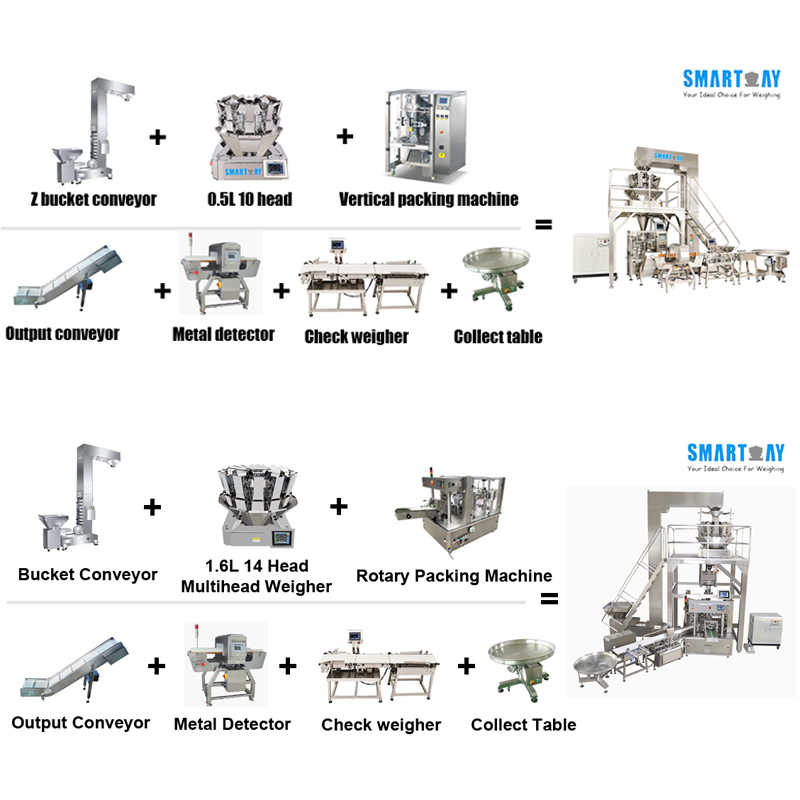

The conveyor has 2 types, they are bucket conveyor and incline conveyor. All the items you need to transport to another place are done with the conveyer. In other words, you can state that the conveyer is like a transportation service for the contents that need to be transferred from one unit to another automatically, without any human interference.

A Multihead weigher is a weighing machine that separates the granular products well and weighs them. Next, it transports it to the packing unit to proceed with packing the food.

Vertical form fill seal packing machineanddoypack packing machineare the common types packaging machine which work with multihead weigher.

Vertical form fill seal machine make and pack products into pillow bag, gusset bag and quad-sealed bag from the roll film; doypack packaging machine seal and pack premade bags.

The working of the Multihead weigher depends upon the workflow it follows. So, here is a working process that a Multihead weigher machine follows.

· The Top cone vibrates with the main feeder to motion the product from the center towards the feeding buckets. There is a difference in the machinery settings that allows you to allocate the right weight to the weighing heads.

· Next, the feeding buckets fill up to the weighing bucket, weigh hopper get am actual weight. At the same time, the system is calculating and finding the accurate measurement, the scale chooses the sum of the combination of weigh buckets to reach the target weight.

· Now, the selected the weigh buckets open the hopper and fill products towards packaging unit.

· Also, to speed up the process, it is advised to purchase machines that have more weighing heads.

NumerousMultihead weigher manufacturersdeploy tons of machines every year. However, you cannot trust all of the Multihead weigher manufacturers. That being the case, it has become challenging to pick a Multihead weigher machine that is robust, efficient, sturdy, and accurate.

What if you are introduced to a brand that checks all boxes of the quality attributes you need in your Multihead weigher machine? It’s theSmart WeighPackaging Machinery.

Their Multihead weigher machines can be used in many business environments like Cereal packaging, ready meals packaging, dry fruits packaging, etc. In addition, their Multihead weigher machines range from 10-32 heads, which can give you the least packaging time with accuracy.

Want to know more about the leading Multihead weigher manufacturers? If yes, stick to the end of the article to discover what makes Smart weigh Packaging Machinery the best bet for your factory.

They Are Robust

When selecting a machinery brand, we always keep the robustness of the machine as our first priority. That's why Smart Weigh Packaging Machinery meets your standards. The machinery that they develop are very sturdy and error-free. Due to the multiple-head functionality, it will distribute the contents according to the weight that you've set.

Efficient

Efficient machinery is what makes a factory prosper! With Smart weigh Packaging Machinery, you'll be able to meet the goals and metrics that you set every day. This will increase production and sales.

Easy to Maintain

You don’t need to follow hard and fast rules to maintain the machinery. Due to the robust engine, the machine’s lifetime is long and rewarding. Now, you wouldn’t need to spend hundreds of dollars to keep the machinery in its finest state.

Affordable

Despite the top-notch functionality of their Multihead weigher machine, the prices are surprisingly low and affordable. That being the case, it is no wonder the best bet among the competitive Multihead weigher manufacturers.

Reputable

Since 2012, Smartweigh Packaging Machinery has been producing robust and highly efficient machines that've helped it increase its reputation. Plus, they don't claim that they're the best Multihead weigher manufacturer; they prove it! By using their machines, you’ll be impressed, as they never fail to disappoint.

Final Thoughts

Multihead weigher machines are best to increase you're the daily production of your company. By reading this article, you would've learned about the basics related to Multihead weigher and how it works.

Also, if you want to purchase from a brand that delivers smart, sturdy, and valuable Multihead weigher machines, then you should go for Smartweigh Packaging Machinery. They have a variety of Multihead weigher machines in their inventory, and you'll surely be able to find the one that suits your factory the best!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved